We are a professional manufacturer, We only accept custom orders.

- Style display

- What we've made

- Brand value

- Trustworthy long-term partner

Create visually stunning paperboard carton boxes with no limitations to craft incredible box experiences for your customers.

Important Note:

We specialize in creating distinctive packaging solutions and exclusively accept custom orders. All our products are tailor-made. Examples shown are for reference only to illustrate the possibilities of custom projects and are not available for direct purchase.

• Features

Eco-friendly and recyclable, featuring a two-piece structure with a strong sense of opening and closing ceremony. It offers excellent protection, high compression resistance, reusability, sturdy construction, and is easy to store and repurpose.

• Application Scenarios

High-end foods, retail packaging, chocolates, macarons, desserts, candy boxes, snacks, nuts, biscuit boxes, pastries, and cakes.

• Keywords

Neck and shoulder packaging gift box, two-piece gift box, snap-fit gift box, double-wall structure gift box, tuck top box, top-bottom paper box, sleeve-style gift box, grayboard tuck top box, hot foil stamped tuck top packaging, eco-friendly tuck top paper box, brand-custom flip-top packaging, holiday gift box tuck top.

| • Brand Name: | Kungfuboy Packaging |

| • Product Name: | Magnetic Rigid Gift Box |

| • Material: | 1200gsm Grey Board (approx. 2.3mm, ~1/11 inch thick), FSC-Certified Paper |

| • Certification: | ISO 9001, ISO 14001, ISO 22301, ISO/IEC 27001 |

| • Style: | Rigid Folding Box with Magnetic Closure |

| • Dimensions: | 28*21*7.5CM (Fully Customizable Sizes Supported) |

| • Color: | Black (Precise color reproduction with CMYK/Pantone matching) |

| • Logo: | Offset Printing (Optional: Embossing / Foil Stamping / UV Coating / Varnishing / Debossing) |

| • Place of Origin: | Made in China (Core Industrial Zone for Packaging) |

| • Minimum Order (MOQ): | 200 pcs (Flexible MOQ Available) |

| • Surface Finish: | Matte (Optional: Matte / Glossy / Soft-Touch / Holographic / Scratch-Resistant) |

| • Lining Type: | EVA (Optional: EVA / Plastic Blister / Sponge Foam / PE Foam / Silk / Paper Dividers) |

| • Accessories: | 2mm Wide Ribbon (Optional: PVC / PET / Ribbon / Satin Ribbon / Handle) |

| • Sustainability: | Compostable |

| • Recycled Fiber Content: | 95% Recycled Material |

| • Ink Type: | Water-Based Ink |

Absolutely! We specialize in custom box printing and would be happy to bring your own designs to life. Your creativity, perfectly printed.

We provide digital proofs with 2D and 3D mockups so you can visualize the finished box before production. For larger orders, we also offer physical samples to ensure everything meets your expectations.

No problem! Our design team is here to help—we’ll create custom packaging ideas for you at no extra cost.

Yes! We offer free virtual samples for standard materials. If you’d like a physical sample, a small printing fee will apply.

Once you approve the design, we’ll share production videos and photos for confirmation before shipping. If the final products don’t match the design or your expectations, we’ll remake your order or offer a refund—guaranteed.

Once you approve the design, we’ll share production videos and photos for confirmation before shipping. If the final products don’t match the design or your expectations, we’ll remake your order or offer a refund—guaranteed.

You can flexibly accommodate every packaging need.

We are not just your supplier, but a strategic partner in achieving your ESG goals and building a green, resilient supply chain. We deeply understand the stringent requirements of international brands for quality, compliance, and delivery.

Let us work together to create for you not just packaging, but a piece of brand art that meets global standards, embodies a commitment to sustainability, and profoundly resonates with consumers.

• Kungfuboy packaging is designed with a sustainability ethos, utilizing materials that are approximately 95% recyclable by weight.

• The paperboard—the rigid inner structure forming the box—is 100% recyclable and fully certified.

• All art paper used in our packaging, including any specialty paper varieties, is certified for sustainable sourcing.

• Our natural kraft paper gift boxes are made from 100% recycled kraft paper.

• The paper surfaces of our packaging are coated with a PP (polypropylene) film. Ideally, this lamination should be removed prior to recycling.

• While laminated materials can be sent to recycling centers, only the paper fibers are fully recovered. However, most laminated paper products have been shown to effectively release paper fibers for recycling in modern pulping facilities.

• Although laminated packaging is less eco-friendly than biodegradable film or unlaminated alternatives, you can still rest assured that our laminated packaging is recyclable.

• The paper, ink, adhesives, and other raw materials used in our packaging boxes strictly comply with international regulations such as EU REACH, US FDA (for food contact), and PFAS bans.

• Certifications: ISO9001, ISO14001, ISO22301, and ISO/IEC27001.

• FSC Certification & Renewable Materials

We prioritize the use of FSC-certified paper sourced from sustainably managed forests, fulfilling our environmental responsibility right from the origin.

• Lightweighting & Structural Optimization

Our engineering team employs innovative structural designs to reduce material usage without compromising protective performance. This helps lower your logistics costs while reducing the environmental footprint.

• End-to-End Circular Design

We are committed to designing mono-material packaging that is easy to recycle and regenerate. By avoiding complex composite structures, we ensure that your used packaging can seamlessly re-enter the next lifecycle loop.

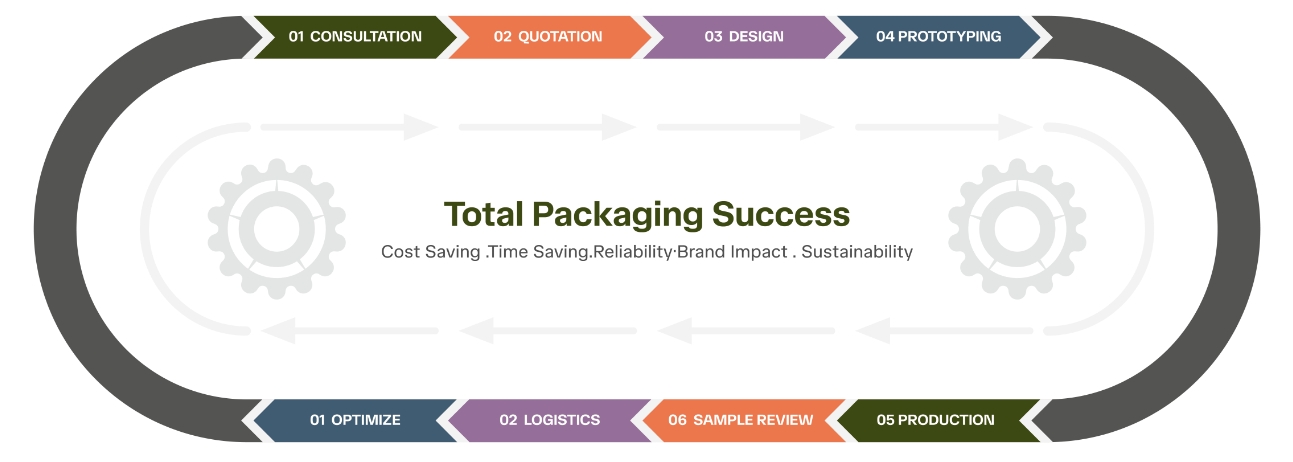

Effective packaging transcends mere aesthetics.

Each business possesses unique objectives, whether it’s optimizing costs or advancing sustainability initiatives.

we address these distinct requirements by offering a comprehensive, modular service across the entire packaging supply chain.

Our experts spearhead each phase, ensuring your needs are meticulously met at every juncture.

Packaging Strategy Packaging Audit

Confirm details Contract Signing

Artwork Design Structural Engineering

Sampling & Prototype Packaging Testing Packaging Optimization

Strategic Sourcing Managed Manufacturing Stringent Quality Control

Check dimensions Structure Materials Process Color

Route Optimization Cargo Optimization Just-in Time Delivery

Project Evaluation Project Optimization

From industry leading packaging solutions aimed at reducing your time and costs for the best ROI.

By leveraging our green packaging and talented team of structural engineers to minimize material usage.

With our award winning packaging designers that focus on building effective first impressions.

With our committed packaging specialists that is here for you 24/7 before and after the project.

• Structural Engineering & Plate Making

Die Production: The confirmed die-line drawing is used to manufacture the cutting die (die-cutting plate), which serves as the mold for the die-cutting process.

• Printing Plate Production

Printing plates (e.g., CTP plates) are created for each individual color based on the final artwork, ensuring accurate color separation and reproduction.

• Bulk Material Sourcing

Based on the approved sample, bulk quantities of specified materials are procured. This includes various paperboards such as Art Paper, White Cardboard, Corrugated Board, and Specialty Paper, along with any required laminates or coatings. Materials meeting specific certifications (e.g., FSC) are sourced accordingly.

• Printing

• Offset Printing: The most commonly used method, suitable for high-volume production of paper products requiring high color fidelity and intricate designs.

• Flexographic Printing: Commonly used for corrugated boxes; fast printing speed, uses water-based inks, making it more environmentally friendly.

• Surface Treatment

• Laminating/Coating: Increases surface gloss or matte finish and enhances abrasion resistance and water resistance.

• Hot Stamping/Silver Stamping: Adds a metallic texture and elevates the overall look.

• UV Spot Coating: Applying varnish to specific areas of the design to create a localized glossy effect,

• highlighting key areas.

• Embossing/Debossing: Using pressure to create an embossed effect on the design, increasing tactile feedback.

• Die-Cutting and Laminating

• Die-Cutting: Using a pre-made die-cutting mold, the printed paper is cut into the designed shape.

• Waste Removal: Removes excess paper edges after die-cutting.

• Laminating: If higher rigidity is required for the packaging (e.g., for premium boxes), the printed paper is laminated to corrugated cardboard or grey board.

• Finished Product Inspection and Packaging

• Inspection: Conduct full or random inspections of finished products. Inspection items include: printing defects, die-cutting inaccuracies, surface scratches, cleanliness, and adhesion strength.

• Packaging: Bundle qualified cardboard boxes neatly, wrap them with cling film or stretch film, pack them into cartons, and prepare for shipment.

This is not a standard sample request, but a vital step to ensure the project stays on schedule and mitigate risks in future bulk production runs.

We look forward to in-depth discussions to ensure this sample will accurately support our shared objectives and lay the foundation for a successful strategic partnership.

Step 1: Specification & Requirement Communication

• Final Artwork: Provide suppliers with your final print-ready artwork,

precise dimensions, and material specifications.

• Define Sample Purpose: for visual design approval or for functional testing (like “drop tests” for shipping boxes or “assembly” for rigid boxes).

• Material Specifications: Specify the exact material grade (e.g., Cardstock, Corrugated Board, Grey Backboard).

• Finishing & Post-Press Processes: Hot Stamping , UV Coating , Embossing, Debossing, Lamination, Die-Cutting, etc.

Step 3: Design & Sampling

• Structural Design: Create 3D structure and die-line drawing.

• Graphic Design: Provide final artwork (logo, graphics, colors).

• Prototype: Factory makes a 1:1 physical sample with actual materials and finishing (e.g., foil stamping, UV).

• Sample Approval: Check dimensions, structure, materials, and print quality.

• Final Sign-off: Approve sample via email or signed document to authorize mass production.

Step 2: Quotation & Payment

• The supplier will provide a quotation based on your specs and confirm the sample lead time (typically 3-7 business days).

• Clarify the logistics method (e.g., courier service) and who bears the cost of sample shipping and delivery (usually the client).

• You proceed to pay the sample fee and shipping cost. For potential large-volume

Step 4: Sample Evaluation & Approval

• You thoroughly inspect and test the received samples for design accuracy, color matching, material quality, structural integrity, and functionality.

• Suggestions for modification: If modifications are needed, provide clear, specific feedback with supporting images.

• Proofing & Approval:

• Review the color proof to finalize copy, graphics, and dimensions. This is the final opportunity to correct any errors from the digital artwork before printing.

• Internal Quality Inspection:

• Prior to shipment, our quality control (QC) team performs a rigorous inspection against your specification sheet. This includes checks for:

• Color Accuracy: Ensuring print color matches the approved proof.

• Dimensional Precision: Verifying all measurements and dieline accuracy.

• Finishing Quality: Assessing the execution of processes like stamping, UV coating, and embossing.

• Overall Cleanliness & Workmanship: Inspecting for scratches, smudges, or glue residues.

• Structural Integrity: Checking the strength and accuracy of folds, creases, and glued joints.

• Visual Inspection

• Color Matching: Compare against the approved color proof to check if color deviation is within acceptable tolerance.

• Finishing Quality: Inspect processes like hot stamping (foil adhesion and uniformity), UV coating/embossing (precision of application), and lamination (smoothness, absence of bubbles).

• Print Quality: Check for any printing defects such as spots, scratches, or misregistration.

• Material Verification: Assess if the material’s feel, thickness (caliper), and stiffness (rigidity) meet the required specifications.

• Structural & Functional Testing

• Dimensional Accuracy: Use calipers to measure critical dimensions, ensuring conformity with the product and dieline specifications.

• Assembly Test: Perform a hands-on assembly to check for smoothness, and ensure that tabs, slots, and glued joints fit correctly without being too tight or loose.

Carefully crafted packaging solutions designed to withstand the rigors of transportation.

Partnering with trusted logistics providers to offer full tracking services, committed to ensuring your goods arrive on time and intact.

• Final Inspection (QC)

A final quality control check is performed on the finished goods based on established standards (e.g., AQL – Acceptable Quality Level).This ensures the outgoing quantity matches the purchase order exactly and conform to quality standards.

• Documentation

The inspection process and final palletized goods are photographed for record-keeping.

• Quantity Verification

The total carton count and the quantity per carton are accurately verified according to the client’s specific packing instructions.

• Documentation Preparation

Commercial Invoice: States goods description, quantity, unit price, total value, and seller/buyer information. Serves as the basis for customs duty assessment.

• Packing List

Details the dimensions, weight, and contents of each shipping carton or corrugated box. Used for customs examination and freight cost calculation.

• Individual Packaging

Each rigid box is individually wrapped in an OPP or PE bag.prevents the custom paper boxes from scuffing, compressing, or absorbing moisture during transit.

• Master (Export) Carton Packing

Robust Carton Selection: Custom-made, seamless and robust 5-ply (AB Flute) or 7-ply corrugated cartons are used for structural support and overall protection.

• Carton Marking

Shipping Label: The carton mark (shipping mark) is clearly affixed, showing

• Incoterms Selection

Standard international trade terms (Incoterms) such as FOB, CIF, EXW, DDP, and DAP are available. (DDP is commonly selected for end-to-end convenience).

• Carrier & Freight Options

We provide a choice of freight solutions—Ocean (Sea), Air, Rail, and Express —with associated costs and estimated transit times for your decision based on needs.

• Estimated Transit Time Guide

Express (e.g., DHL): 3 days

Express (e.g., UPS): 5-7 days

Express Ocean Service: 30-35 days

Standard Ocean Service: 45 days

Rail Freight: 55-60 days

• Please note

All transit times are estimates and can vary due to factors like shipping lane conditions and manufacturing origin.

• Shipment Tracking

Upon dispatch, we provide the tracking number (e.g., Bill of Lading number for sea freight, Air Waybill number for air freight) for real-time monitoring of your cargo’s location.

• Final Delivery (Last-Mile)

Process: After customs clearance is completed, a local logistics partner (e.g., a trucking company) transports the goods from the port to your designated warehouse or address.

• Shipment Receipt & Inspection

Upon receipt, please inspect the external packaging for any visible damage before signing the Proof of Delivery (POD) to confirm acceptance.

• After-Sales Support

Should you have any concerns regarding the received shipment, or discover any damage or quantity discrepancies, please notify us immediately to initiate the claims process.

• End-to-End Process Monitoring

We provide comprehensive oversight throughout the entire production and logistics cycle for complete peace of mind.

• We employ scientifically engineered damage-resistant packaging—such as corrugated boxes and protective inner materials—for source-to-destination safety.

• By partnering with trusted logistics providers and standardizing operating procedures, we ensure reliable handling throughout transit.

• Full-process real-time tracking and proactive exception alerts keep you continuously informed.

• All shipments are backed by comprehensive shipping insurance and a clear claims commitment, guaranteeing secure, on-time, and intact delivery of your goods.

• Gold Standard” Sample Archiving: Upon your written confirmation of the approved sample, One copy is kept for your records, and another is stored in our QC department’s reference library on the production floor, serving as the definitive benchmark for first-article inspection. This archived sample constitutes a legally binding physical standard.

• Parameter Solidification: Sample confirmation extends beyond aesthetics. We generate a detailed Production Process Control Sheet that digitizes and standardizes every element of the sample. This comprehensive document includes:

• Material Specifications: Precise paper weight (GSM), origin, brand, color, grain; exact type of coating or specialty finish.

• Structural & Construction Techniques: Exact dimensional tolerances (e.g., ±2mm), creasing line depth and specifications, die-cutting layout.

• Color Standardization: Use of specific Pantone Matching System (PMS) codes or provided CMYK values from printed proofs for objective color management.

• Surface Finishing Details: Type of lamination (gloss/matte), precise location and gloss level of spot UV coating, foil stamping material grade, embossing/debossing height.

• Sustainability & Compliance Certs: Certified post-consumer recycled content percentage and other relevant material certifications.

• First-Article Inspection

At the start of mass production, the first several dozen units from the production line are collected. Our quality control team then performs a point-by-point comparison against the archived standard sample using specialized equipment—such as vernier calipers and a colorimeter under a standard light booth. Bulk production proceeds only after the First-Article Inspection Report is approved by both parties.

• In-Process Patrol Inspection

Throughout the production run, our QC personnel conduct random inspections of in-process products at fixed intervals (e.g., hourly). They focus on critical, variable aspects like color consistency, die-cutting accuracy, and mounting alignment to promptly identify and correct even minor deviations.

Prior to packaging and warehousing for dispatch, we execute the final and most comprehensive line of defense.

• 100% Inspection Combined with Sampling Inspection

For high-end products or products with critical appearance surfaces, we implement 100% full inspection, ensuring every item leaving the factory meets the required standards. For standard products, we adhere to the AQL (Acceptable Quality Level) sampling inspection standard—an internationally recognized method for quality acceptance that scientifically represents the quality level of the entire batch.

• Final Sample Comparison

Finished products are randomly selected from the bulk production and compared side-by-side with the sealed “Approved Master Sample” once more, culminating in a final inspection report.

• Process Visibility

As your supplier, we welcome the delegation of third-party inspection agencies (e.g., SGS, BV) during our manufacturing process. We also provide visual documentation, such as photos or videos of critical milestones like the First Article Inspection (FAI) and bulk order packaging, enabling you to monitor progress remotely and transparently.

• Contractual Safeguards:

Our contracts explicitly stipulate that “the mutually sealed and approved sample shall serve as the sole basis for final quality acceptance.

We maintain long-term partnerships with certified paper and material suppliers to ensure consistent quality and stable sourcing of raw materials. Through detailed production scheduling and logistics coordination, we effectively manage timelines from manufacturing to delivery. This end-to-end control guarantees on-time order fulfillment and maintains the quality consistency of your packaging products, such as corrugated boxes and custom cartons.

• Tiered Supplier Management : We implement a tiered management system, classifying our suppliers into strategic, core, and general categories. For core suppliers of materials like paper, we engage in deep collaboration and rigorous audits, which includes joint demand forecasting to ensure stability for our manufacturing partners.

• Safety Stock Maintenance : To mitigate supply chain volatility, we proactively maintain a 2 to 4-week safety stock for commonly used materials, such as specific grammage grey board and art paper, ensuring uninterrupted production.

• End-to-End Traceability : We have established a robust traceability system that tracks your finished products back to the specific batch of paper used. This not only meets environmental compliance but is also critical for rapidly identifying, locating, and initiating recalls in the unlikely event of a quality issue, minimizing potential impact.

• Visualized Capacity & Planning: Our factory utilizes an ERP system for detailed production scheduling, ensuring the timely allocation of equipment, manpower, and materials. This provides reliable planning visibility for our clients.

• Overall Equipment Effectiveness (OEE): We conduct dedicated daily monitoring of OEE metrics. Maintaining optimal equipment performance is fundamental to our on-time delivery capability as a supplier.

• In-process Quality Control: Quality checkpoints are established at every critical stage of the production line. This “quality-built-in” approach enables the immediate identification and correction of issues, ensuring consistent output.

• Structured Communication SOP : A standardized procedure ensures timely status updates at every critical order milestone—including confirmation, materials ready, production start, completion, and shipment. This provides clear visibility into your product’s progress through our factory operations.

• Proactive Early Warnings : Should we identify potential delays, such as a longer lead time for a specific raw material, we immediately notify all affected clients. As your supplier, we believe in transparently communicating the impact and collaborating on solutions.

• Multimodal Transport & Contingency Planning : Our operations are well-versed in sea, air, and rail freight options. As a reliable supplier, we maintain strong partnerships with four primary freight forwarders to ensure flexible and resilient shipping solutions.

• Optimized Packaging Design : We collaborate with clients to design “stackable” or “nestable” packaging structures. This strategic approach maximizes container space utilization, directly reducing transportation costs for your orders from our factory.

• Export Expertise : Our team is well-versed in the customs regulations and labeling requirements of destination countries. This expertise prevents costly detentions of your goods at port due to documentation issues, ensuring smoother delivery.

We implement real-time tracking and management across all stages, ensuring full transparency and control from material sourcing to final delivery.

We are committed to providing a transparent and efficient end-to-end communication experience. By integrating packaging consultation, real-time project tracking, and a responsive support system, we ensure you have continuous visibility into the progress of your custom packaging project. Our team delivers prompt, professional technical support and optimization suggestions, enhancing collaboration efficiency and ensuring the precise implementation and timely delivery of tailored packaging solutions.

• Your Concterns:

“When issues arise, will the supplier respond promptly? Will they proactively inform me about production or logistics updates? Can this project be delivered on time, to the required quality, and within budget? Is the process transparent? Will we constantly need to follow up?”

• Regular Progress Reports: Weekly or bi-weekly proactive production progress reports, including images/videos.

• Milestone Notifications: Automatic updates at key stages (e.g., raw material arrival, production start, first-article inspection completion, container loading, vessel departure/flight takeoff).

• Clear Response Time Standards: Email responses within 4 hours during business hours; 24/7 WhatsApp/phone support for urgent matters.

• Dedicated Account Manager: Key clients are assigned a fixed contact who understands the project thoroughly, offering one-stop service to eliminate the need for multiple follow-ups.

• Your Concerns:

“What happens if quality issues are found after delivery, or goods are damaged during transit? Will the supplier shift blame, or actively collaborate to resolve the problem?”

• Clear After-Sales Policy : Clearly define quality standards, return/replacement procedures, and claim timelines in writing.

For transit damage, clarify the collaboration process with insurance providers and proactively assist customers in filing claims.

• “Solution-First” Approach : Acknowledge and respond to complaints immediately, Launch a prompt investigation and keep the customer informed throughout the process.Offer fair and actionable solutions

• Root Cause Analysis & Feedback : After issue resolution, provide a brief Root Cause Analysis report detailing what went wrong and the preventive measures implemented.

• Your Concerns:

“Is this low price a bait? Will various additional fees appear later? What is the total cost of ownership?”

• Professional and Detailed Quotations

Standardized Quotation Format: Includes: Project description, clear specifications, model, weight, specifications/process, unit price (USD), quantity, total price (USD, etc.), and remarks.

• Clearly Defined Logistics and Liability Terms

Clearly use Incoterms 2020 rules in the quotation and contract, such as FOB, CIF, EXW, DAP, etc.

• Advance Communication of All Potential Additional Costs

Payment Fees: Such as bank fees for TT payments (usually each party bears its own costs).

Certification and Testing Fees: Special certifications (CE, RoHS, FDA, etc.) require additional fees.

• Your Concern:

Will the requirements and specifications I provide be accurately understood and executed by the team? Are the quotes and contract terms clear and unambiguous?

• Enhancing Language Skills & Utilizing Tools:

• Staff interfacing with clients must possess fluent business English proficiency.

• Tools like Grammarly should be used to review emails, ensuring professionalism and accuracy.

• All external documents (quotations, contracts, specification sheets) must undergo language review by specialized personnel.

• Standardized Communication Process:

• Confirmation and Recap: After receiving order requirements, provide clients with a written recap and confirmation of all details to ensure mutual understanding.

• Visualization of Documents & Data:

•Supply easily understandable packing lists, commercial invoices, and bills of lading, ensuring all data is accurate and error-free.

Order a full production with us and we will waive your sample & prototyping costs as well as receive our dedicated 360° packaging service which removes any packaging difficulties you may have so you can focus on what really matters.*

*Certain conditions apply depending on your order size. Speak with our specialist for more details.