We are a professional manufacturer, We only accept custom orders.

- Style display

- What we've made

- Brand value

- Trustworthy long-term partner

Test your packaging before you invest. Order custom samples to verify fit, structure, and design—and mitigate potential risks with minimal cost.

While it requires some upfront time and cost, this approach is the most reliable way to identify and resolve potential issues early on. This small step prevents major setbacks, protecting your brand presentation and your bottom line.

Low-fidelity printed samples with custom sizing and material, produced using digital CMYK printing. No finishes or add-ons included.

Flat CMYK color proof printed digitally.

Best for reviewing near-final color representation before full production.

Flat color proof including finishes and add-ons, printed on actual production equipment. Ensures accurate color matching for final print runs.

Physical Pantone color swatch for precise color validation. An essential tool for maintaining brand color consistency.

Not sure which sample to go with?

Here’s what we recommend!

Not sure which sample to go with?

Here’s what we recommend!

Compare our custom samples to see which one best suits your needs!

Digital Print ProofCMYK printed proof on proofing paper | Structural SampleUnprinted size sample | Simplified SampleLow fidelity CMYK printed prototype | Press ProofPrinted proof with finishes & add-ons | Pre – production Sample1:1 high-fdelity printed prototype | |

| Format | Flat document | Physical prototype | Physical prototype | Flat document | Physical prototype |

| Best for… | Providing color references when there are no color matching or Pantone requirements. | Verifying the size and structure. | Verifying the size and structure, and seeing a low – fidelity outcome of the print. | Seeing the exact outcome of colors, artwork, finishes, add – ons on the same material used in production. | Seeing the exact outcome of colors, artwork, finishes, add – ons as a final production product. |

| Accurate colour (in relation to production) | √ Production will match approved print proof color. | × | √ | √ | |

| Colours Supported | √CMYK ×Pantone ×White Ink | √CMYK ×Pantone ×White Ink | √CMYK √Pantone √White Ink | √CMYK √Pantone √White Ink | |

| Offset Printing (used in production) | × Uses digital printer: – Different prints of digital print proofs could look slightly different. – Cannot be used for color matching of Pantone matching. | × Uses digital printer: – Colors may differ from colors printed with offset printers. – Different Prints of Simplified Samples could look slightly different. – Cannot be used for color matching of Pantone matching. | √ | √ | |

| Exact Material (used in production) | × Uses proofing paper | √ | √ | √ | √ |

| Diecutting Machine (used in production) | × Uses CAD cutter: – Paper may show small creases and cracks. -Scores (fold lines) may be uneven. – Slightly harder to fold. | × Uses CAD cutter: – Paper may show small creases and cracks. -Scores (fold lines) may be uneven. – Slightly harder to fold. | √ | ||

| Finishes/Add Ons | × | × | × | √ | √ |

| Cost (USD) | 25 | 19 / 39 / 99 | 25 / 59 | 149 | 149 / 300+ / 400+ |

| Reimbursable | From 500 units | From 500 units | From 500 units | From 5000 units | From 5000 units |

| Timeline (Excluding delivery) | 2 – 3 days | 3 – 5 days | 4 – 5 days | 7 – 12 days | 7 – 12 days |

Confirm your design intent with a physical sample.

Color Accuracy

Screen designs (in RGB) and physical prints (in CMYK) always differ. A physical sample is the only reliable way to verify whether color variations are acceptable.

Material & Feel

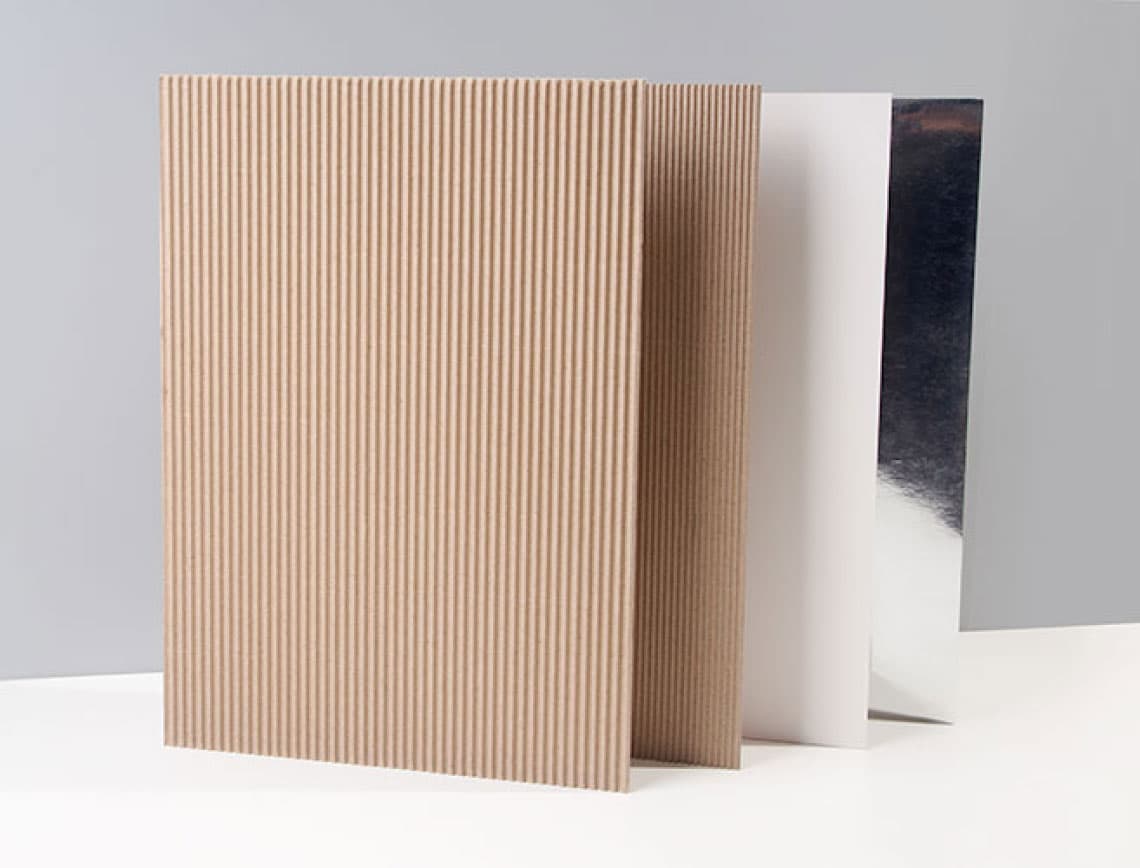

Paper weight, texture, finish; plastic flexibility or rigidity; metallic look—some qualities can only be judged by holding the real product in your hands.

Finishing Effects

Evaluate specialty treatments in person: the shine and adhesion of foil stamping, the depth of embossing or debossing, the gloss of UV coating, and the precision of die-cuts.

Physical samples serve as the legally binding reference for quality assurance.

How It Works

Once you approve and countersign a sample, it becomes the “reference standard” for mass production. All finished goods must match the approved sample in quality.

Why It Matters

This process prevents disputes caused by misaligned quality expectations between supplier and buyer. If final products deviate from the approved sample, you are entitled to request rework or a return.

Test the waters before a full-scale launch.

How It Works

Share samples with key accounts, distributors, or internal teams to gather honest feedback on product appearance, feel, and unboxing experience.

Why It Matters

This step helps you avoid investing in packaging that may not resonate with your target audience—preventing costly missteps before they happen.

Absolutely. The full sample kit cost will be refunded once you place your first production order with us.

Yes, we can. Start a structural design project with us to create the perfect insert tailored to your product.

Production typically takes 12–16 days, with 16–21 days for larger orders. Shipping time depends on the method you choose.

Air freight takes 7–21 days, sea freight 26–71 days. If you need goods earlier, consider splitting your shipment using both air and sea options.

Definitely. That’s where our core service begins. We specialize in 100% custom production. After receiving your requirements, we’ll provide a quote and sample timeline. Once confirmed, we’ll start producing your samples.

Yes. We always recommend getting a quote first.

Our standard process: Share your needs → Receive a detailed quote → Confirm → Pay the sample fee → Sample production begins.